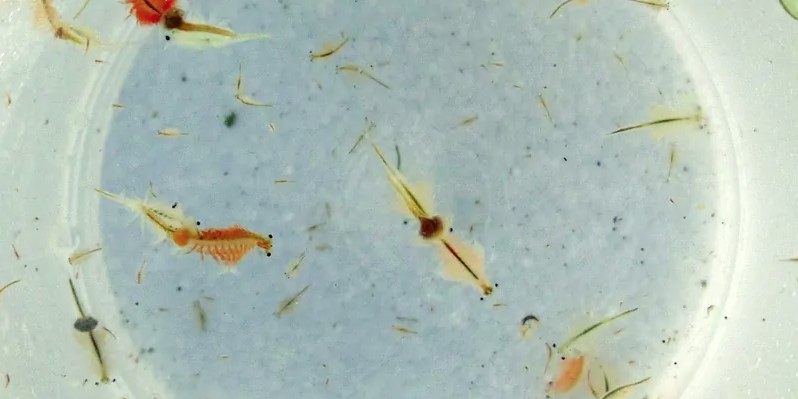

It’s not every day that a gag gift at a holiday party sparks a new line of research, but that turned out to be the case for Heather Maynard, a polymer scientist at the University of California, Los Angeles (UCLA). As she watched little shrimp-like sea monkeys emerge from what was once a bit of powder mixed with water, she wondered, “well, actually, how does that work? How does it work that you can have a powder and then have a shrimp? It turns out trehalose is involved.”

Trehalose is a sugar commonly found in plants as well as bacteria, yeast, and fungi. Trehalose is involved in protecting these and other organisms including worms and tardigrades from damage during desiccation, intense heat, and other stressful conditions (1). By investigating how trehalose stabilizes proteins and other molecules, Maynard wants to use trehalose’s superpowers to stabilize life-saving drugs so that they can withstand harsh environmental conditions, including a lack of refrigeration. She and her team developed a trehalose-based molecule called poly(trehalose methacrylate) (pTrMA) that acts as an excipient. So far, Maynard and her team have shown that pTrMA stabilizes insulin to withstand excessive heat while preserving its function in mice, but pTrMA is just one of many trehalose-based polymers Maynard plans to develop for better drug formulations (2).

How did you become interested in developing more stable drug formulations such as for insulin?

Some of my friends told me that their children were having difficulties with the stability of their insulin, for example while hiking or doing other outdoor activities. I thought to myself, I really would like to do something to increase the quality of life for people who have to take these drugs. Let’s make sure that these drugs are always safe, even out of the refrigerator. There are countries where consistent refrigeration is not available. We would like to have these drugs accessible and safe for long periods of time for people in those countries as well.

How did you come up with your trehalose-based excipient, pTrMA?

At the time of that sea monkey moment, we were very interested in protein stabilization. We wanted to enhance the pharmacokinetics of a protein, and because polymeric excipients increase the pharmacokinetics of drugs, we wanted to make a polymeric form of trehalose. We started with a polymethacrylate backbone, which is similar to the backbone of Plexiglass. It was pretty well established that that polymer is biocompatible, so that’s one of the reasons we chose it. We placed trehalose directly onto that backbone.

How does trehalose protect against desiccation and extreme temperatures?

It’s actually somewhat controversial. It’s not exactly clear how trehalose protects fragile proteins, but there is good evidence for different mechanisms. It’s thought that if an organism goes without water, trehalose can replace the water by hydrogen bonding directly to the protein, lipid, or whatever it is. Another hypothesis is that perhaps trehalose entraps water, so it doesn’t allow for desiccation from the protein. Then there’s another mechanism called vitrification where trehalose forms a glassy layer around the protein, holding it physically in place. We recently discovered that our pTrMA polymer behaves via an entirely different mechanism.

How does pTrMA work?

For our recent paper in ACS Applied Materials & Interfaces (2), we had two goals: to better understand pTrMA’s stabilizing mechanism and to assess the safety of pTrMA in vivo. To assess its stability, we heated pTrMA combined with insulin to 90°C for 30 minutes, and then we kept it in the refrigerator at 4°C and periodically took samples to see what percent of the insulin stabilized with pTrMA had degraded over time. In the end, we found that pTrMA stabilizes insulin in the refrigerator for almost one year, and during that process, we noticed that pTrMA does two things: It prevents aggregation of the insulin, and it significantly decreases the incidence of deamidation, a chemical change that insulin can undergo. However, we still don’t know how exactly pTrMA prevents aggregation or deamidation.

You mentioned safety. How did you test that?

Over the years, we had seen that various trehalose polymers were quite stabilizing, but we hadn’t really investigated whether they were safe on a systematic level. We first looked at the immune response in mice, and we saw that pTrMA did not stimulate an antibody or a cytokine response, which was good.

We also looked at the biodistribution and excretion of the polymer with and without insulin, and we saw that the mice excreted most of it. We also looked at the plasma lifetimes of insulin with or without the polymer present, and we didn’t see a difference. This was not a full pharmacokinetics study, but from what we saw, it didn’t seem like pTrMA caused any alarming changes.

What was your reaction to these positive safety data in the mice?

I was excited to see that. I didn’t think it would be unsafe because the components are just trehalose, which is already used in food and many drug formulations, and the plexiglass backbone. But we never know what might happen when we combine something, so I was really happy that it looked promising. That doesn’t mean that it can go into humans tomorrow, but it means that there’s nothing saying that we shouldn’t go forward and test it further.

What do you plan to do next with pTrMA?

We’re looking to optimize the synthesis of pTrMA. I’m very interested in partnering with people in industry who would like to take this further. I can do additional studies myself, but we don’t have the massive scope of a company. So, partnering to see if we could move it forward would be fantastic.

What are some of your goals for your trehalose and drug stabilization research?

The National Science Foundation recently funded a big center between UCLA and the University of California, Santa Barbara called the BioPolymers, Automated Cellular Infrastructure, Flow, and Integrated Chemistry Materials Innovation Platform (BioPACIFIC MIP). The purpose of the center is to use bacteria, yeast, and fungi to make new monomers and polymers and to use automation to make the process much faster. I’m very interested in using bacteria, yeast, and fungi to make different trehalose type molecules that we can use for polymers or materials that might have different kinds of properties. With the automated polymerization component, we can make hypotheses and test thousands of potential drug stabilizers at once. Maybe we can use that to come up with something that is even better than trehalose.

References

- Hibshman, J.D. et al. Mechanisms of Desiccation Tolerance: Themes and Variations in Brine Shrimp, Roundworms, and Tardigrades. Front Physiol 11 (2020).

- Gelb, M.B. et al. Poly(trehalose methacrylate) as an Excipient for Insulin Stabilization: Mechanism and Safety. ACS Appl Mater Interfaces 14, 37410-37423 (2022).